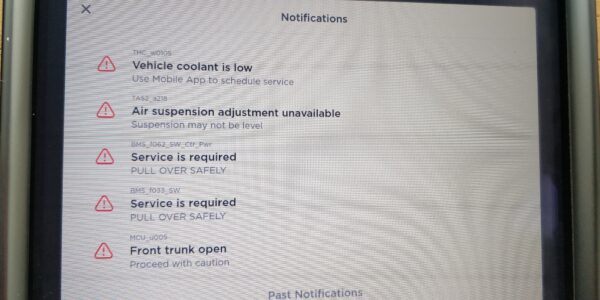

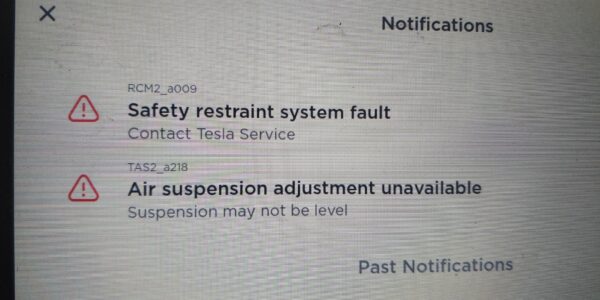

In the previous update the car was pretty much ready for inspection, but there were still some safety system related alerts and the air suspension was not working. Tesla normally self-clears the alerts when the problem is fixed but safety system or RCM (restraint control module) is an exception, as well as air suspension. Both are related to safety so I guess it makes sense.

To clear these alerts turned out to be a bit more difficult than we initially thought.

It was December 2020. Because at that time Tesla did not offer any kind of diagnostic tools and we did not know any aftermarket ones we contacted Tesla to get the alerts cleared. The first time slot for them was almost a month away, mid January. They said it's first time for them (in Finland) someone want something like this done. So we couldn't do much - just wait.

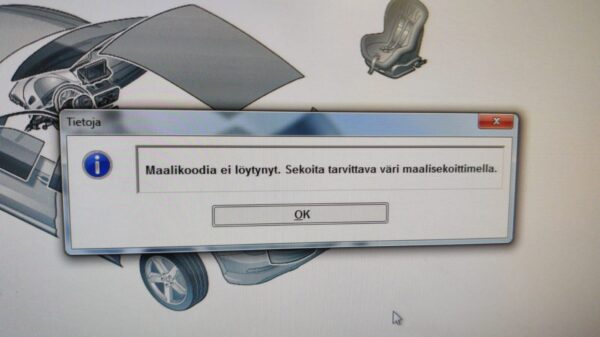

We had tried to gain access to Tesla's Toolbox (which is their own diagnostic application). According to their website (service.tesla.com) it was supposed to be possible to purchase a time limited access, workshop manuals etc. We created an account and tried to activate with a credit card, but it didn't just work. We called their "hotline" several times and always telling it was "another department" that takes care of this and come back. And they never came. It all looked like they never wanted to give access and the whole website was just created to fulfill EU requirements. My friends told me I should sue Tesla to court...

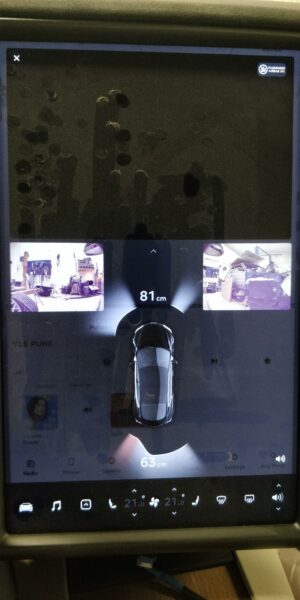

On the morning of 13th of January I drove the car to nearest Tesla service center (only two in Finland - this one was more than an hour away). The air suspension was not working and I could see from the MCU screen that the front was going down a bit all the time. Anyway, I was there when the service opened at the morning. I gave them the key and stayed there myself to wait and work with my laptop. After couple of hours they asked me to come to a small meeting room where they explained that things are not proceeding - they had not done their homework properly. They had now found that according to Tesla policy they would need to make a high voltage test before they are allowed to do anything else. They couln't even tell how much this test costs... "not several thousand euros". And even before that I need to request this test and make a report for them of all the repairs I've done to the car. And that's not all - they gave me a notice (SC-15-00-006 Salvage-Titled Vehicle Notification) where they explained that Supercharging will be disabled. They also gave me SC-18-00-007 Owner Notification and Acceptance of Unperformed Repairs with slots for signatures and vehicle information. That was not filled anyway.

I had heard from US stories about disabling SC from salvage vehicles, but I was hopeful this was only a US thing as I had written with a guy from UK who had taken his car to Tesla for similar crash alert clearing without losing the supercharging.

At this point I was pretty pissed off. We could get the alerts cleared. They had been able to fill the A/C system and adjust the headlights though. Although I don't know how they did the headlight adjustment when the suspension was not working and front was clearly lower than rear. And I had to pay 400 eur for all this.

On my way home I stopped by a DC charger (non-Tesla) and that still seemed to work. On my way home the front was still going down, but I could still get back home safely. I had already before explained my situation on a Facebook group and on my way home I was contacted by a guy who had contacts to Eastern Europe who might be able to help me. I then decided we will fix this car without any help from Tesla.

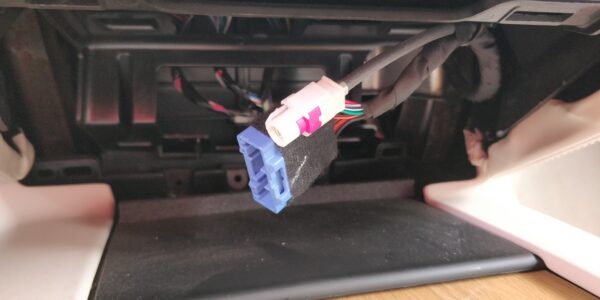

The contacts in Eastern Europe needed an internet access to my car and a router so they could configure a VPN access to the car. After a couple of weeks it was time to try to clear the alerts. I had previously bought a Fakra diagnostic cable that was connected from the Autopilot computer's ethernet to the router and from that to the internet and to the computers of the helpful hackers in Eastern Europe.

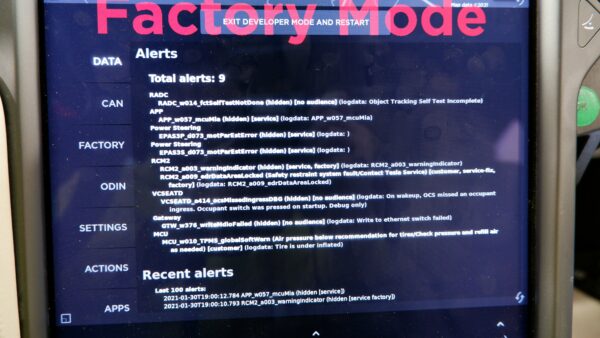

At that time we did not understand yet what was going on, but in a few moments the car was in factory mode. I was following the displays of the car and instructions from the hackers. Every now and then they asked to reboot the car or gateway and install software updates that the car was downloading. Apparently they had Toolbox access and some other software they used to control the car.

Anyway, after all this the hackers were able to clear the alerts from the air suspension, but not the RCM. I had to take the RCM module out of the car and send to the hackers for manually clearing.

The module is in pretty tricky position under the dash but eventually got it out and shipped to the guys in Ukraine. It took about a month until the unit came back. Plugged in the car and the alerts were gone!

Challenges with air suspension continues

So the car was finally OK and was able to pass the inspection in the end of 2021. After driving a few days the front started to drop overnight. For a long time we tried to find a leak - we thought perhaps there's a leak in valve block that had been removed during the repair process or perhaps it was damaged. No leak was found. Finally took the front strut and bag out and finally found a leak. We thought perhaps it had bent in the accident or something like this. Anyway, a new strut was ordered. 1500 EUR.

It was also time to change summer tires so I decided to buy Momo wheels from Rimfix RMX has their own custom wheels but lead time was too long at this point. These Momo wheels were designed with Tesla spec so no need for spacers or any other adapters. The only challenge was the really long drive shaft end - couldn't fit the center cap to the wheel.

For that issue the fix was fairly simple... because I did not want to remove all four drive shafts I decided to cut them while still in the car. A bit sweaty process, but the end result was good.

Looking good with bags empty and 10cm blocks of wood on the lifting locations. The wheels are 9,5x21 ET 32. Also applied a Ceramic Pro coating on a new paint.

Some people told that the suspension needs to be calibrated after changing a strut but that's not correct. Just replace and drive. For two days. Then failed the rear end...

While driving on a bag surface there was some weird noise coming from the back. Just like an exhaust was hitting rear axle on a classic car. While driving kids to school one morning there was a small pop from the rear and some whooshy sound after that... and rear down completely. That's how a rear bag failed. Was too lazy to figure out where that weird clatter sound was coming.

This time I decided to study what was going on with the struts. I was hopefuly to be able to change only the airbag. Couldn't find the replacement anywhere.

Apparently the bag had been somehow wrinkled wihen the car was down and we applied pressure to the system. The bag had remained wrinkled inside the aluminum tube housing and couldn't straigthen up and while driving it eventually rubbed broken. That's another 1500 eur well spent! This time a new part was found from Tesla's local warehouse and didn't need to wait two weeks for a new part like with front strut.

Like this was not enough - after a few weeks of driving the front started to drop again... this time the reason was on driver side.

I did not care to check the front end while working on the rear. Also the front bag had somehow misaligned inside the aluminum housing. This had caused the bag to slowly rub itself broken. Probably this is the reason why the passenger side also failed in the first place. Now I also understood why I heard some banging noises when first manually filling the system at the paintshop.

After spending 4500 eur for new struts I can really say I learned my lession on how to fill a completely deflated air suspension. An advice for all - try to fill the system while the car is at a lift.

I now have three good shocks waiting if some day there are aftermarket bags available for these adaptive air suspension struts.

Fast charging works

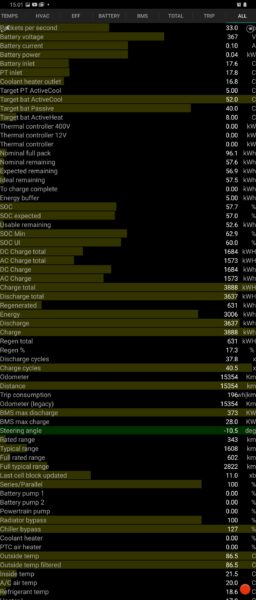

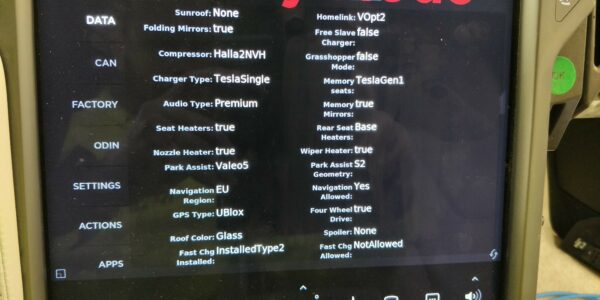

Although Tesla disabled Supercharging, other fast charging is till working on non-Tesla DC chargers. That can be seen on car's config on Factory Mode - when Fast Charging is 'Not Allowed', Other Fast Charging is still 'Allowed'. There's not been DC chargers on my neighborhood so charging has been almost completely AC charging at home.

Afterwords

I'm writing this roughly a year later when I initially thought the car is ready. Just clear a few alerts and do the inspection. In practise I've driven the car since May 2021. Bought this for my own use and planning to keep it for a long time.. if something more appealing does not show up. Model S is a really nice car - especially being a ten year old model - and if you forget there's really limited service nework and for enthusiasts it's quite difficult to work with these cars.

During sring 2021 we also purhcased some diagnostic tools for Autokierrätys L&G to be able to do more with these cars - like put the car into Factory mode etc. However, Tesla keeps making life more difficult on updates - for example these new Intel based cars are really tricky to work with other than factory tools.

Speaking of factory tools - Tesla finally opened up access to Toolbox at fall of 2021. It's an external version so I assume they can still do more at official service center.

During a year we have learned so much about Teslas and now able to offer all kinds of services and repairs together with Autokierrätys L&G. We have for example replaced A/C compressors, repaired door handles and interior heater PTCs. All typical failure points of Model S.

Although my car does not have any warranty left, I feel not anguished. I feel whatever comes up, we can repair it. We have more and more contacts all over the world now. We support Right-to-repair and ready to do a bit more work to get the cars running without special tools from Tesla service. Life without Supercharging has not been an issue. There's been one single time it would have been nice to charge at SC. There's so many HPC chargers around and even cheaper than Tesla's. After all, we got this car ready and repaired way cheaper than buying similar non-damaged Tesla.

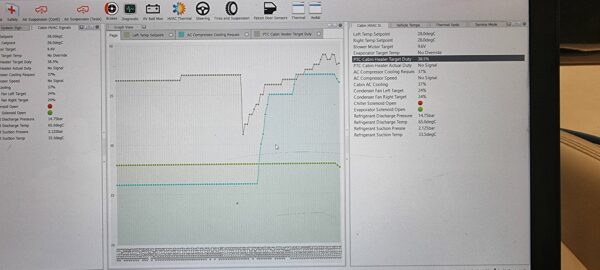

Speaking of heating - during winter there's been a bit of an issue with interior heating. It's heating, but not at full power. You need to keep full heat and blower at high speed to keep the windscreen clear. Tesla's cabin heating is not really this bad. At the time of writing this issue has not been solved - we've tried replacing the PTC and checking all sensors. Also no alerts.

Generally speaking heater issues have been an problem in Teslas this winter. Several Model S's have been requiring PTC heater change and simulteneously Model 3's and Y's have had problems with heat pumps. Californian car manufacturer still seems to need some more excercise on conditions at North. Also the door handles and door glasses are not hazzle-free during the cold months.

These should not be an issue in our next project car - Audi e-Tron.